Coverall MULTI® Splash

Cat. III, typ 5 i 6

Thanks to a completely new technology of (artificial) staple fibers, terms such as protection and comfortable clothing have been redefined. This coverall has been designed in such a way as to meet the high quality requirements that are imposed on such clothing during painting work. The suit is completely free of paint damaging substances.

Breathable and antistatic multilayer non-woven fabric obtained by the "under the filament" method (EN1149-5), rejection values of substances containing alcohol and oils (type 6), as well as the finest dust and particles (type 5). For many years, the proven design (three-piece hood - moves according to the anatomy of the head and a sewn-in gusset in the crotch - less tension on the seams when kneeling and bending down, which reduces the risk of tearing) was adopted for the MULTI® Splash suit.

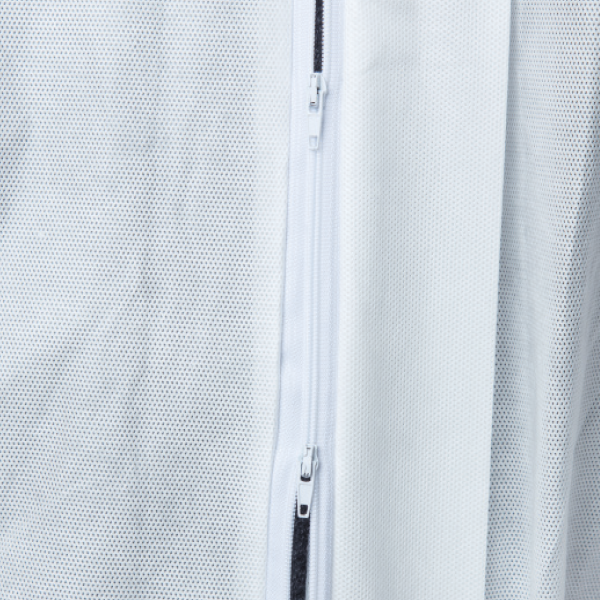

Additional comfort: two-way zipper and textile trim strips in the sleeves together with elastic bands (legs, waist, hood) ensure the best freedom of movement with an optimally fitted form to the body!

Application:

Treatment of the external surface (varnishes, paints, coatings), utilization of old environmental loads (e.g. asbestos), decontamination works and waste disposal. Contact with hazardous materials and substances without pressure in tanks and pipes, inspection works, surveys, construction works, investigative work in the police.

Material:

Multilayer polypropylene (SMMS)

Colour:

White

Available sizes:

S, M, L, XL, XXL, XXXL

Basis weight:

60 g/m2

CE:

| Typ 5 | EN ISO 13982 |

| Typ 6 | EN 13034 |

| Antyistatic | EN 1149-5 |

| Against radioactive contamination | EN 1073-2 |

Penetration data EN 368

| Chemical | Physical state | CAS | Repellency index |

| Sulphuric acid (30 %) | liquid | 7664-93-9 | 81,6 % |

| Sodium hydroxid (10 %) | liquid | 1310-73-2 | 97,3 % |

| o-xylene (undiluted) | liquid | 95-47-6 | 5,4 % |

| Butan-1-ol (undeiluted) | liquid | 71-36-3 | 33,2 % |

Material properties:

|

Fabric physical properties |

Test method | Unit | Result |

EN Class |

| Abrasion resistance | EN 530 | cycles | > 10 | 1 |

| Punture resistance | EN 863 | N | 7 | 1 |

| Ignition resistance | EN 1146 | No further flaming, no drop information | ||

| Tensile strength | EN ISO 13934-1 | N | 120 L / 57 Q | |

| Trapsodial tear resistance | EN ISO 9073-4 | N | 66 L / 34.3 Q | 2 |

| Surface resistivity | EN 1149 - 5 | Ohm | 2,5 x 10^9 | |

| Seams strength | EN ISO 13935-2 | N | > 125 | 4 |